Translational biomedical engineering: Intelligent inhalation system / 2018

Novel color sensors are less expensive to manufacture

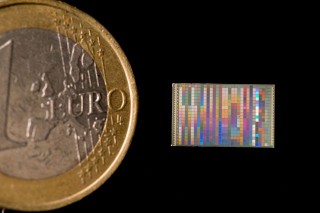

In the FOWINA project, the Fraunhofer Institute for Integrated Circuits IIS in Erlangen and the Fraunhofer Institute for Silicate Research ISC in Würzburg have developed novel color sensors with a special microlens arrangement. The sensors can be realized directly on the chip and combine multiple functions in a minimum of space. Their extremely slim design makes the sensors suitable for a wide range of applications, such as in mobile devices or color-adjustable LED lamps.

more info