Creative solutions for individual requirements in the field of glass and glass ceramics

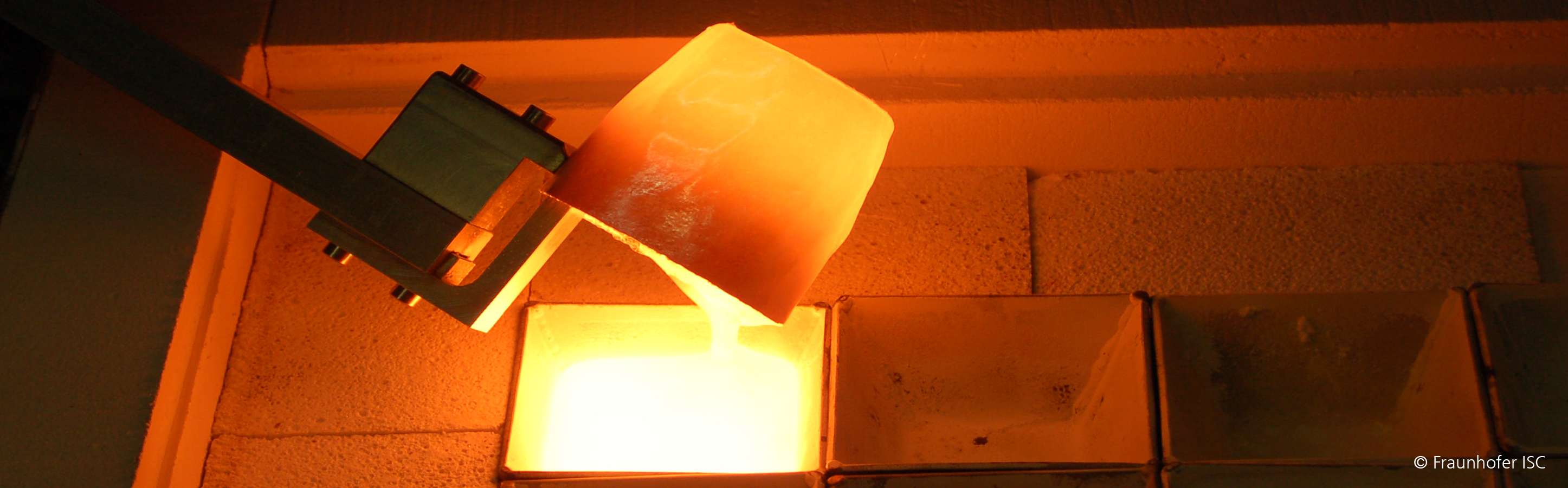

Since the founding of the institute in 1926, the development, manufacture and characterization of special glasses and glass ceramics has been one of the core competencies of the Fraunhofer ISC in Würzburg.

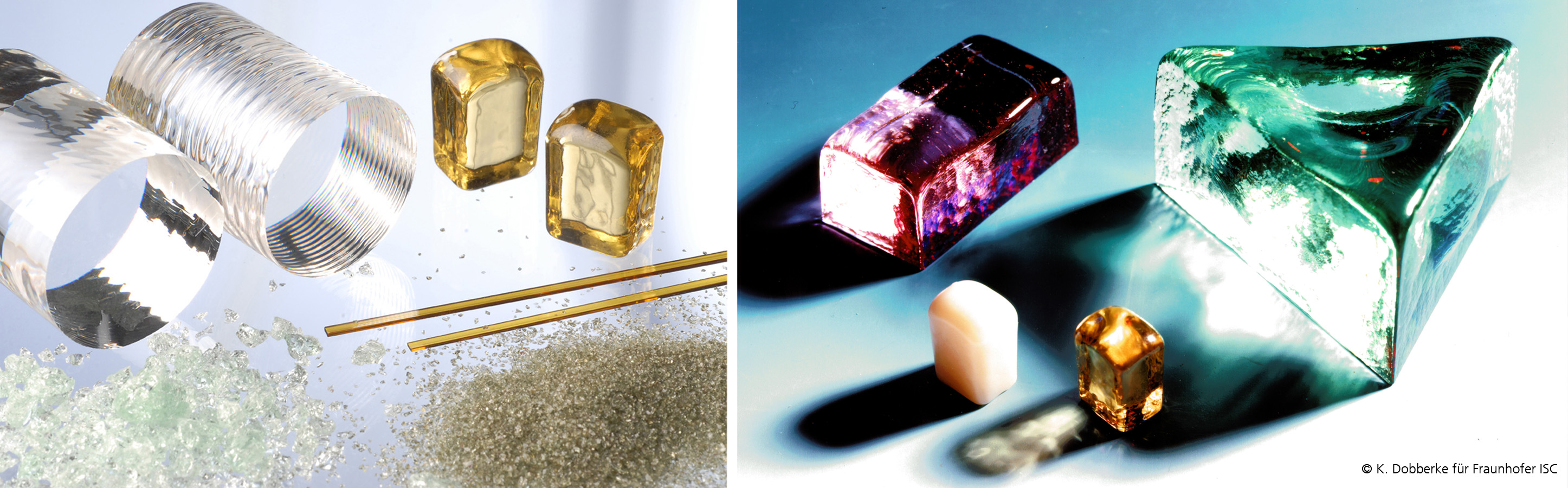

We develop special glasses and glass ceramics for individual requirements - no matter if temperature stable, electrically conductive or gas-tight. For specified applications, we manufacture glass in the form of rods, tubes, semi-finished products, powders and fibers and advise on glass composition, glass coating and glass analysis. Further topics are other silicate mineral materials such as plasters, paints, mortars and concrete.

From the creation of a new glass system to the design and construction of a special glass melting plant - the Glass and Mineral Materials Division covers the entire process with its focus on material and process development, characterisation and testing technology (certified according to DIN EN ISO 9001:2015).

Click here to go directly to our Glass Services page.