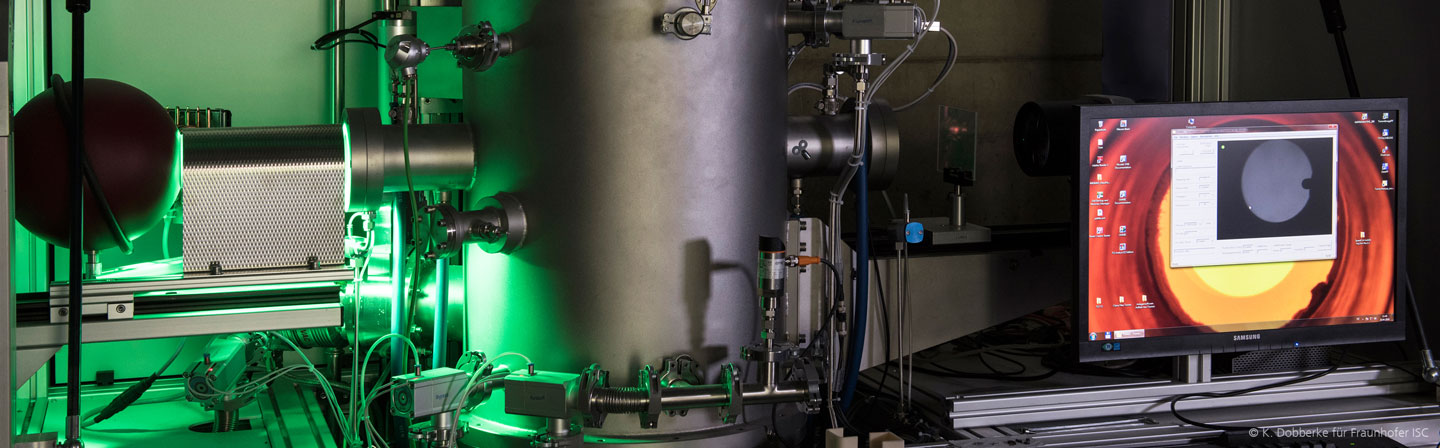

The production of glass and ceramics, and of a number of sol-gel materials, requires precise knowledge of thermal processes and temperature-related activities within a material’s structure. An exact process control is decisive for the later quality of the product and also determines the energy consumption of the manufacturing process. The Fraunhofer ISC, backed by many years of experience, has accumulated comprehensive know-how and understanding of heat treatment processes and related analysis and optimization tasks like the thermal characterization of materials. The Institute also develops special measuring methods and devices for a thermooptical material characterization.

Current R&D priorities

- Glass melts

- Manufacturing of ceramics, sintering

- Thermal post-treatment (curing, subsequent annealing)

- Device development

Our competencies

- Melting and heat treatment processes from room temperature to 2000 °C required for the production or processing of given materials

- Optimization of heat treatment processes

- Matching of process parameters and material properties

- Materials analysis

- Thermooptical characterization

- Process analysis, in particular, heat treatment processes (sintering, infiltration)

Our services to customers

- Characterization of the behavior of solid materials or melts during heat processes

- Examination of debinders, pyrolysis, sintering, melting and infiltration processes

- Measurement of dimensional changes, sinter shrinkage, warping, thermal extension

- Measurement of gas phase reactions: weight loss, gas emission

- Thermophysical characterization of solid materials: thermal conductivity, creep resistance, emissivity, high-temperature stability, high-temperature Young’s modulus, thermal shock resistance

- Melt characterization: wetting, viscosity

- Simulation of heat flows and temperature fields during thermal processes

- Development of temperature cycles of shorter total duration (cold-cold), e.g. during debinding and sintering

- Development of thermal processes with less rejects and finishing efforts

- Development of temperature cycles/heating conditions with lower energy consumption

- Development of customized high temperature measurement methods

Further information

- Read more about our Center of Device Development CeDeD.

- Find out more about our thermal characterization of glass on www.glas-dienstleistungen.de.

- Find out more about thermal processes in the manufacturing of ceramics on the website of our Fraunhofer-Center for High-Temperature Materials and Design HTL.

Expert information

- Center of device development CeDeD

- KLIMATOM – In-situ characterization of materials with climate change conditions

- TOM-AC - Precise material data in controlled atmosphere

- Tommiplus - A thermooptical measuring device for the control of thermal processes

- Screening apparatus for glass development

- Fraunhofer-Center for High Temperature Materials and Design HTL