PFAS - the "forever chemical"

PFAS is the abbreviation for per- and polyfluorinated alkyl compounds, also known as "forever chemicals". These synthetic fluorine compounds include a variety of more than 10,000 substances. They have excellent technical properties such as water, dirt and grease repellency.... As a result of these properties, they have been in use for decades in a wide range of applications. Their molecular structure - consists of short, medium or long chain molecules with bonds between carbon and fluorine. The bond between these two atoms is very stable and therefore difficult or impossible to break down in the environment.

→ Press Release (chemsec) »Blood tests show high-level EU politicians are polluted by PFAS«

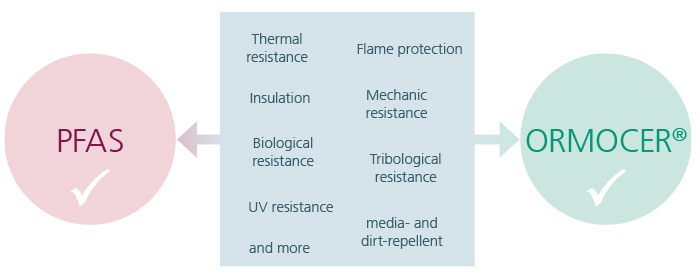

PFAS ban in the EU - now what?

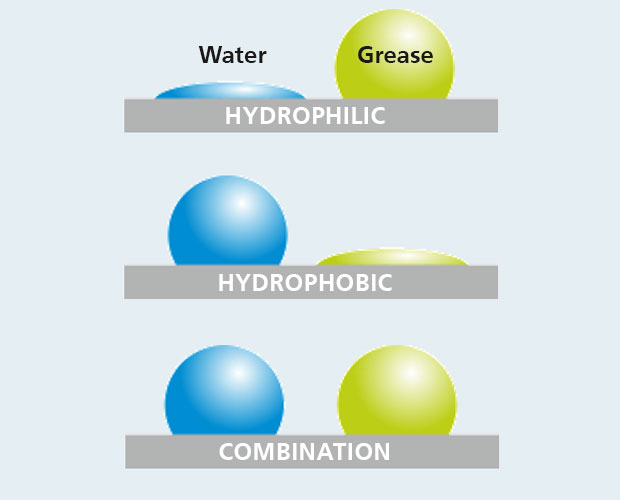

The combination of physical and chemical effects in ORMOCER® coatings enables tailor-made solutions replace PFAS.

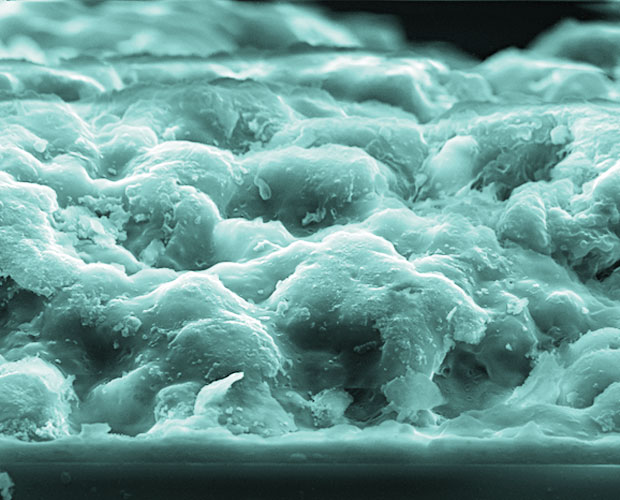

ORMOCER® belongs to the group of inorganic-organic hybrid polymers and was developed at Fraunhofer ISC more than 30 years ago. It is characterised by high hardness, resistance to wear, temperature and environmental influences. It can be considered as a material class in its own right and combining the advantages of inorganic (glass or ceramics) and organic (polymer) materials in a new, hybrid material that can contribute to the careful use of resources and sustainable materials management.