Initial research

ShaPID - Shaping the Future of Green Chemistry by Process Intensification and Digitalization

01.2021 - 12.2023

The chemical industry is indispensable for a large number of industrial value chains and is one of the most important drivers of new product developments and innovations. Global challenges in the areas of climate protection, energy and resource efficiency, coupled with demands from society and politics for green, sustainable chemistry, have led the chemical industry to set itself ambitious goals for defossilizing its production processes and establishing circular, greenhouse gas-neutral material and energy conversion. This transformation calls for major research and development efforts.

The nine Fraunhofer institutes cooperating in the lead project "ShaPID" want to support the chemical industry in these efforts in a targeted manner by pooling their applied research to achieve the challenging sustainability goals and, at the same time, intensifying their R&D relations with one of the most innovative industries.

3D veneering - individual, fully automated production of 3D-structured dental veneers

01.2021 - 12.2023

Veneers are one of the classic dental restorations. In Germany alone, 3.3 million dental veneers are used every year. The aim of the SME project "3D veneers" is the individual, fully automated production of 3D-structured dental veneers using the inkjet process. Customized color gradients and translucency can thus be produced quickly and cost-effectively while maintaining optical, thermal, chemical and mechanical properties.

For this purpose, starting glasses of dental glass-ceramics are to be individually adapted in terms of shape and color, applied to various framework structures by means of 5-axis inkjet printing and then fired. By using already approved dental glass-ceramics, all relevant target properties are ensured and complex color gradients are possible.

VisioMEL - In vitro test platform to assess the effect of therapies against malignant melanoma

01.2021 - 12.2023

Malignant melanoma is one of the most dangerous cancers and leads to about 3000 deaths per year in Germany. To date, preclinical development of new therapies has been dependent on animal studies, but this leads to an error rate in translating preclinical results into clinical phases of about 95%. New three-dimensional in vitro models of melanoma show higher predictivity, but are relatively difficult to analyze or can only be cultured for relative periods of less than one month, further reducing predictive power for long-term therapies.

VisioMEL aims to establish and validate an in vitro testing platform to assess the effect of therapies against malignant melanoma. To this end, an interdisciplinary consortium of scientists with a background in tissue engineering, device engineering and microsystems technology will cultivate a previously developed organotypic model of malignant melanoma under conditions that allow long-term cultivation of the models for longer than four weeks. In addition, the tumor progression in the models will be monitored using lensless microscopy in conjunction with appropriate image analysis.

The aim of CarbonID is to endow particles/powders with a unique ID, i.e. a kind of barcode, by combining colored luminescent nanoscale components into a particle. In a classical approach, organic dyes or inorganic Cd-based quantum dots could serve as luminescent building blocks. The former are problematic because they are not durable (and thus fade), the latter because they are toxicologically questionable. In order to use barcode particles to make the leap to digital materials, it is crucial to overcome the aforementioned drawbacks of classical luminescent components.

Recent basic research results have revealed a highly interesting class of luminescent material: carbon that can glow in a wide variety of colors, so-called CarbonNanoDots. So far, such objects can only be produced in small quantities and with poor reproducibility. Within the framework of CarbonID, colored luminescent carbon will be produced continuously in order to demonstrate the basic manufacturability of barcode particles and the marking of any material component.

The aim of the OVERDOSE research project is to develop an abuse protection for opioid dosage forms, which is only activated by an overdose: When the normal dose is taken, the analgesic is released unhindered; in the event of an overdose, the abuse protection is activated and a release of active ingredient is reduced to a tolerable level.

At the end of the project, a dosage form of an opioid is available as a "proof-of-concept" which contains a concentration-dependent overdose protection. This so-called "overdose" effect will be demonstrated in biorelevant (gastrointestinal tract-simulating) dissolution experiments at Fraunhofer ITMP as part of the project and is expected to reduce the drug release by at least 80% per unit in case of overdose. In contrast, the drug is fully released at normal doses.

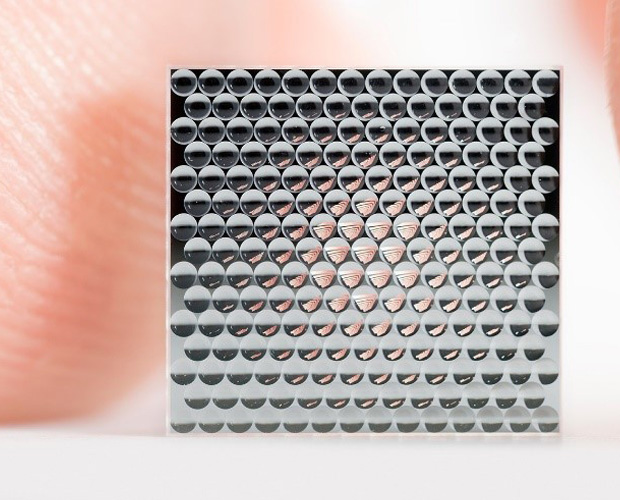

Next-Level Optics Manufacturing - Innovative (Partially) Digital Process Chains for the Production of Complex Components Made of Glasses

04.2021 - 12.2021

The precise production of complex glass components for optical systems is time-consuming, material-intensive and costly, both when using molding tools and cutting processes. The institutes have developed alternative digital manufacturing technologies that have not yet become established in (series) production. The project aims to establish these technologies in the new competence center "Innovative Glass Processing IGP" for SMEs and to use new process sequences of these technologies. To this end, a combined technology portfolio is being developed and rounded off with individual complementary development steps.