Initial research

The production of functional and true-to-shape objects using various 3D printing processes has developed enormously. However, the printed result of plastic-based objects often does not meet the expectations of product designers / consumers, neither visually, nor haptically. They desire product realism in a variety of applications. REVISE aims to enable printing results with previously unrealizable visual properties through optimized 3D printable materials and material combinations.

Optical effects in polymer-based materials can be created by combining different materials, for example, by cleverly arranging layers with high refractive index contrast, adjusted transparency, translucency or scattering behavior. REVISE will develop hybrid polymer composites that meet optical and process requirements, expand the material portfolio for 3D printing, and are compatible with commercial standard inks.

At the end of the project, an expanded material portfolio will be available for the multijet process that can be used to achieve the defined optical characteristics. "Inverse rendering" simulations to realize these optical effects will be validated; demonstrators will be produced using 3D printing.

CAR-T-Patch - Cytokine microneedle patch to enhance the efficiency of CAR-T cancer immunotherapy

07.2021 - 06.2024

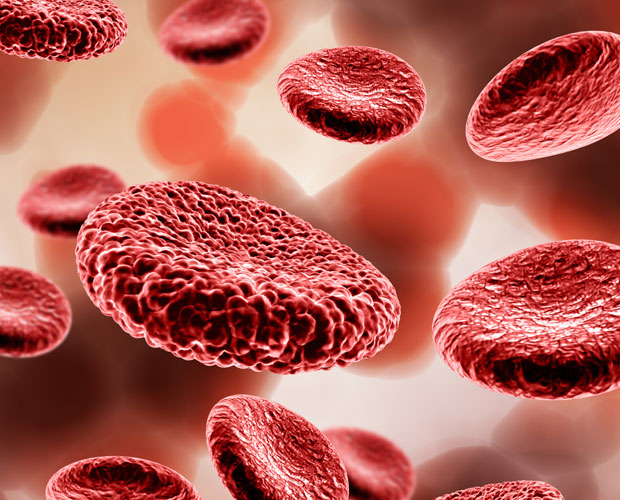

Cancer is one of the leading causes of death worldwide. Cancer immunotherapy with chimeric antigen receptor (CAR)-T cells is considered a breakthrough innovation and is already approved for the treatment of blood and lymphoma. However, CAR-T technology has had little success in solid tumors to date because CAR-T cells cannot penetrate solid tumors and are also inactivated in the tumor environment.

In the SME project CAR-T PATCH, a microneedle patch is being developed that significantly enhances the efficiency of CAR-T cell therapy in solid tumors close to the skin. The bioglass-based microneedle patch is used to deliver messenger substances (cytokines), which attract CAR-T cells to the tumor and ensure their cancer-killing function, via the skin into the tumor area in a minimally invasive manner. The efficiency of a local and precisely dosed cytokine milieu will be validated using established 3D in vitro and in vivo skin cancer models.

At the end of the project, a versatile platform technology will be available, which can be rapidly transferred to many other immune and cell therapies by exchanging the transported messengers. As a therapy-accompanying product for CAR-T and other cell therapies, the pharmaceutical industry, especially in the field of immuno-oncology and ATMPs (Advanced Therapeutic Medicinal Product), is targeted as a future field of medicine.

SensPflast - Technology platform for diagnostic and therapy-supporting treatment through sensor patches

01.2022 - 12.2024

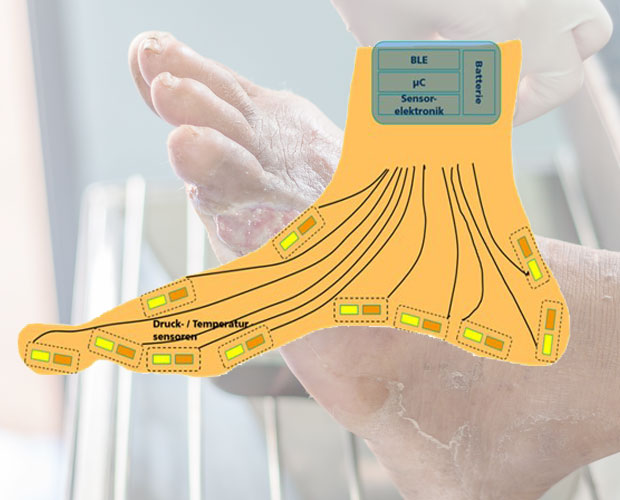

In the SensPflast project, a technology platform for diagnostic and therapeutic wound patches is to be developed on the basis of flexible film substrates with innovative sensor technology. SMEs active in the field of wound care will gain access to a technology portfolio that allows the realization of customized multi-sensor patches. In the project, a sensor patch will be developed as a technology demonstrator that addresses diagnostic and therapy-supporting aspects of diabetic foot syndrome. It enables continuous, digital and networked therapy monitoring of pathological pressure, temperature and wound secretion conditions. On the basis of this information, treatment requirements can be identified at an early stage and the necessary medical measures can be optimized so that serious secondary diseases and, consequently, the corresponding follow-up treatment costs can be reduced.

Due to the increasing prevalence of diabetes in modern industrial societies, there is a high potential for application and exploitation. Comparable, highly integrated solutions of soft sensor modules for parallel recording of different medically relevant parameters, which can be integrated into bandages, stockings, bandages or seat cushions individually for each patient, do not exist. In the project, the Fraunhofer Group partners ISC, IIS and EMFT will deepen and combine their expertise in the fields of sensor technology, packaging as well as electronics and communication for medical wound care.

MIYA - Establishment of the production of biomimetic cellulose yarns via electrospinning

07.2022 - 06.2025

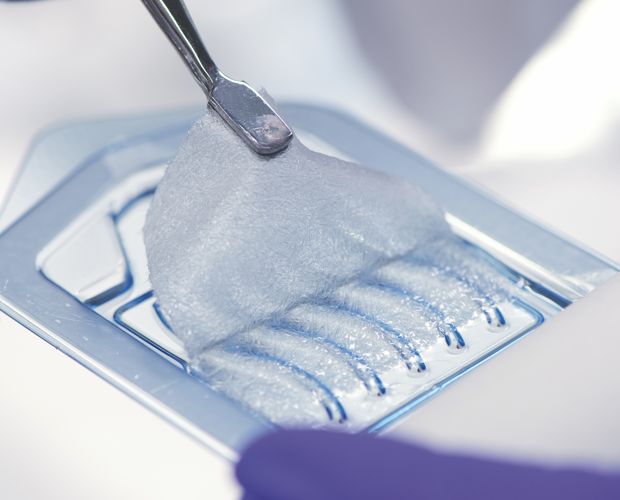

The gold standard for severe tendon injuries is the implantation of an autograft or allograft. If neither autografts nor allografts are available, the implantation of synthetic tendons is the only alternative. However, current synthetic implants show unphysiologically high characteristics in their elastomechanical properties. They also lack the ability to self-heal, lead to inflammatory abrasion particles in the long term and thus limit the willingness of physicians and patients to use them.

Utilizing biomimetic or hierarchical structure principles, this project will develop a cellulose processing technology that will improve elastomechanical properties and thus enable their use as tendon implants. In addition to the already existing excellent immunological compatibility, an in vivo tissue integration is achieved by the collagen fiber-like diameter of the electrospun fibers and the functionalization of the cellulose molecules with cell adhesion promoting groups.

The targeted biomimetic structure of the cellulose yarns covers the structured size hierarchy (subnano to nano/submicron to micron scale) over at least 3 levels. In addition to the known biocompatible pure cellulose, derivatives such as cellulose acetate or cellulose sulfate are used to adjust their performance with respect to cell interaction. Finally, the tissue integration potential in the bioreactor is assessed under the influence of physiological strain rates.

PreInfect - Development of antimicrobial coated tamponades for the prevention of bacterial infections of nasal wounds

07.2022 - 06.2025

Antimicrobial resistance (AMR) is one of the greatest and ever-increasing threats to human health worldwide. Alternatives to conventional drugs, such as antibiotics, are therefore urgently needed. Satisfactory solutions are particularly lacking in wound care, so that the healing of numerous cutaneous and internal wounds is often delayed by infections. Due to increasing numbers of cases in hospitals and inadequate treatment options, the health care system records annual costs in the billions. Currently, established modifications of wound dressings, adapted by the addition of antibiotics or silver ions, constitute available possible forms of application. The problems of these wound dressings lie on the one hand in their toxicity, which must always be considered borderline, and on the other hand in their efficacy, which must be critically evaluated: due to the risk of resistance, the use of antibiotics is increasingly prohibited.

Antimicrobial peptides (AMPs) belong to a new class of biological therapeutics that have the potential to substitute antimicrobial agents used so far. PreInfect describes a promising perspective for modern wound care. By modifying an established wound dressing with antimicrobial peptides, a demonstrator for a natural, antimicrobial and highly innovative medical device will be developed. This demonstrator will address the SME dominated target market of medical devices. In addition, already established human 3D tissue models for infections with pathogenic bacteria and fungi will be further developed in order to address not only the market of antiviral drug testing but also the market of antibacterial and antifungal drug testing in the future.

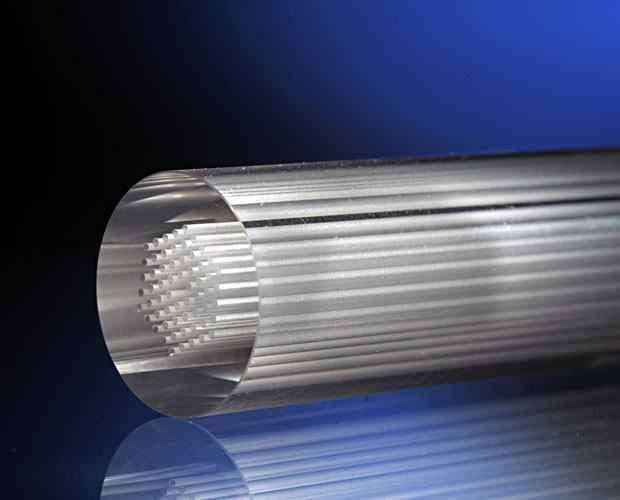

Photonics is one of the most challenging fields of development with a wide range of applications for the realization of new computer systems, state-of-the-art ultrahigh-resolution metrology, mobile sensor technology and material sciences. By using modified electromagnetic waves, single photons and the combination of different photon energies, qubits are controlled and read out in quantum computers, chiral molecular complexes are analyzed and novel computer architectures with ultrafast communication between the individual components are realized. However, a prerequisite for these developments and applications is the availability of suitable beam-guiding and beam-shaping elements up to optical memories and highly selective spectral filters. While novel three-dimensional photonic structures are constantly being conceived and simulatively researched for the progress of these elements, their fabrication is still based on the established processes, which are subject to strong limitations with respect to their geometrical freedom and are therefore not or only very conditionally suitable for the fabrication of three-dimensional structures.

The goals in the "LAR3S" project are therefore the research and realization of novel photonic structures for waveguiding, field modification and optical storage and filtering, as well as the necessary manufacturing processes based on selective laser structuring and laser modification processes. Only the use of these manufacturing technologies enables the fabrication of three-dimensional optical structures, such as low attenuation Photonic Crystal Fibers (PCF) or microresonators with dynamic dispersion control.

The aim of the project is to develop a viable concept for unmanned, fire-resistant aerial drones for close-range operations in fire scenes and over fire areas. Possible applications of the novel drone are residential fires and forest fires as well as fires in industrial plants. They are used for mission coordination, reconnaissance and - in further development - emergency response. So far available drones are limited by short flight duration and ambient temperatures of up to max. 50 °C.

The use of a damage-tolerant high-temperature material for all components of the drone that are subject to high thermomechanical stresses and a thermal protection container in which all temperature-sensitive electronic components are housed is intended to solve the dilemma of existing drones. For this purpose, a novel overall concept for the drone architecture has to be developed: for propulsion, shrouded propellers made of CMC (O-CMC) are used; for the heat protection container and the sensor technology, concepts are transferred that have already been developed for the application area of thermoprocess technology / industrial furnaces.

The use of O-CMC instead of conventional materials, especially for the rotors aerodynamically stressed in the drive train and for the exposed structural components subject to shock and thermal shock, allows the missile to stay longer in otherwise inaccessible areas at temperatures above 400 °C. The optics and sensors are also constructed of temperature-resistant materials. Signal processing takes place at comparatively low temperatures inside the thermal protection container, which is additionally cooled by a phase change material.

BioLIGHT - Technology and process development for continuous photochemical-assisted biocatalysis for the synthesis of fine chemicals

02.2021 - 01.2024

Fine chemicals represent an essential basic building block in the chemical industry. The chemical syntheses of fine chemicals pass through several catalyst-based stages, requiring long changeover times and elaborate process controls. To enable competitiveness in this area, the industry is seeking new production/process technologies and materials. Strategic developments have to consider in particular upscalability and catalyst immobilization. BioLIGHT is therefore developing a novel, modular technology and process platform that enables the targeted synthesis of fine chemicals by continuous photochemical-assisted biocatalysis. The BioLIGHT technology is based on three key elements: (1) novel hybrid catalysts, (2) new processes using micro-process engineering, and (3) an innovative plant concept. The modular design is a key innovative step in BioLIGHT, allowing easy adaptation to synthesis cascades as well as process scaling.

The feasibility and functionality of the BioLIGHT technology and process platform will be demonstrated using two cascade reactions for the synthesis of industrially relevant fine chemicals. If successful, the new BioLIGHT technology and process platform can be used in a variety of application fields and will strengthen the Strategic Research Fields (SFF) Bioeconomy as well as Resource Efficiency and Climate Technology and especially the offer for the lead market Chemical Industry.

SoftMaterialRobotics (SoMaRo) - Soft materials and technology integration for soft robotics

04.2021 - 03.2024

Today's common rigid gripping tools of robots are not able to quickly grasp soft and delicate objects with non-uniform geometry such as fruits, vegetables and other foods without damage. The interdisciplinary SoMaRo project aims to develop a unique robotic gripping technology based on soft, adaptively controllable soft kinematics with integrated soft actuators, sensors and electronics based on novel smart materials that can be selectively deformed using software control with electric fields. The first-time integration of soft actuator, sensor and electronic layers in soft, compliant soft kinematics, combined with adaptive real-time control & feedback control algorithms, creates intuitively sensitive grippers. These novel gripping tools for robots enable the defined enclosure and secure holding of the object to be gripped with a sensitivity and intuitive grip safety comparable to the human hand.

With the combination of soft kinematics, integrated soft actuators, soft sensors and soft electronics, feedback for adaptive gripping force control is achieved. Such a gripper system can be seamlessly integrated into existing robot systems. For verification purposes, two modular robot gripping tools with different actuator principles are realized as demonstrators, which for the first time enable fast automated and process-safe handling without damage. To prove the transferability to other areas, the realization of an adaptive robot gripper suitable for the assembly of flexible components will follow.