Fraunhofer relies on Automation Technologies in Medical Research

As a pioneer in applied research, the Fraunhofer-Gesellschaft brings together the expertise of 23 separate Fraunhofer facilities to develop new development and production technologies for innovative cell and gene therapeutics, as well as vaccines, in the “Production for Intelligent Medicine” innovation cluster.

As a first step of the project, a concept for a modular pilot plant for the automatic production of these therapeutics is to be developed combining both Industry 4.0 and Health 4.0.

Personalised healthcare with advanced therapy medicinal products, so-called ATMP, forms a milestone in the treatment of complex illnesses, such as cancer. So far, these ATMP are largely produced manually, which is both time-consuming and expensive and, moreover, production is only possible for a limited number of patients. At the current time, this severely limits the availability of innovative therapeutic agents for patients who urgently need them.

In parallel with this, the most recent case of the COVID19 pandemic has shown the tremendous challenges which arise in the context of the development and subsequent production of specific vaccines to respond to novel health risks.

This is where the Fraunhofer “Production for Intelligent Medicine” innovation cluster comes in – bringing together the biological and medical know-how of the institutes in the production of cell and gene therapeutics as well as of vaccines using expertise in automation technologies and the autonomous control of industrial processes.

Under the leadership of the Fraunhofer Institutes for Cell Therapy and Immunology IZI, Experimental Software Engineering IESE, Manufacturing Engineering and Automation IPA, Molecular Biology and Applied Ecology IME as well as Industrial Engineering IAO, the scientists are aiming to transfer automation technologies to medical research and applications in the production sector. In its first stage, the project aims to develop innovative concepts for the digital, AI-supported, robot-assisted and automatic production of pharmaceuticals as well as cell and gene therapeutics and vaccines.

Increasingly, tailor-made therapeutic strategies are raising hope for improved treatment success, e.g. in oncology. In consequence, this Fraunhofer innovation project pursues the aim of dramatically increasing the availability and quality of state-of-the-art personalised cancer and immuno-therapies as well as of vaccines. Moreover, automation technologies can also help in drastically reducing costs of production and, ultimately, significantly alleviate the burden on our healthcare systems.

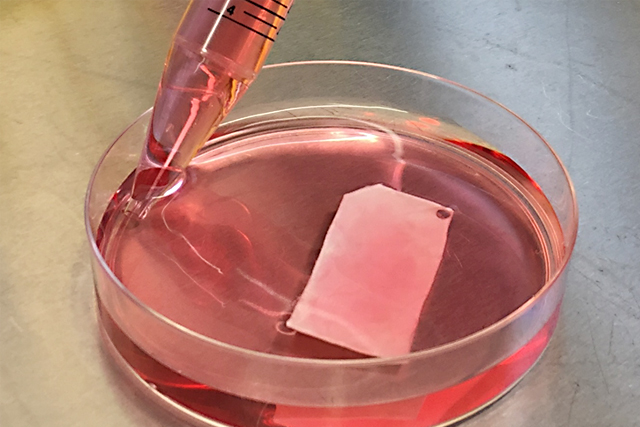

The Fraunhofer Institute for Silicate Research ISC is participating in the joint project with its Translational Center for Regenerative Therapies (TLZ-RT). The TLZ-RT contributes its many years of expertise in GMP-compliant qualification (GMP stands for Good Manufacturing Practice - guidelines for quality assurance of production processes and environment), production and characterisation of human 3D tissues/ATMPs (e.g. skin, intestine, cartilage) from primary cells and iPS cells and combines this with the advantages of a robot-based automation unit. Non-invasive analytical methods such as impedance spectroscopy developed and patented at TLZ-RT or optomechatronic imaging modules are evaluated for automation. The modular structure of the automation platform at the Fraunhofer ISC makes it possible to implement complex cell biological processes. The advantages lie in the high degree of standardization and reproducibility in the manufacture of ATMPs and thus in the increase in product quality. The implementation of conventional laboratory equipment in the automated system facilitates the implementation of the automation strategy and also enables timely adaptation to other manufacturing processes.

With regard to the regulatory challenges and official communication, the TLZ-RT of the Fraunhofer ISC acts as an expert in questions concerning the clinical application of ATMPs and as a pharmaceutical manufacturer of these "Novel Drugs". Currently, the TLZ-RT is also acting as GMP manufacturer of a cartilage implant within the framework of a European phase II multicentre study.

Last modified: