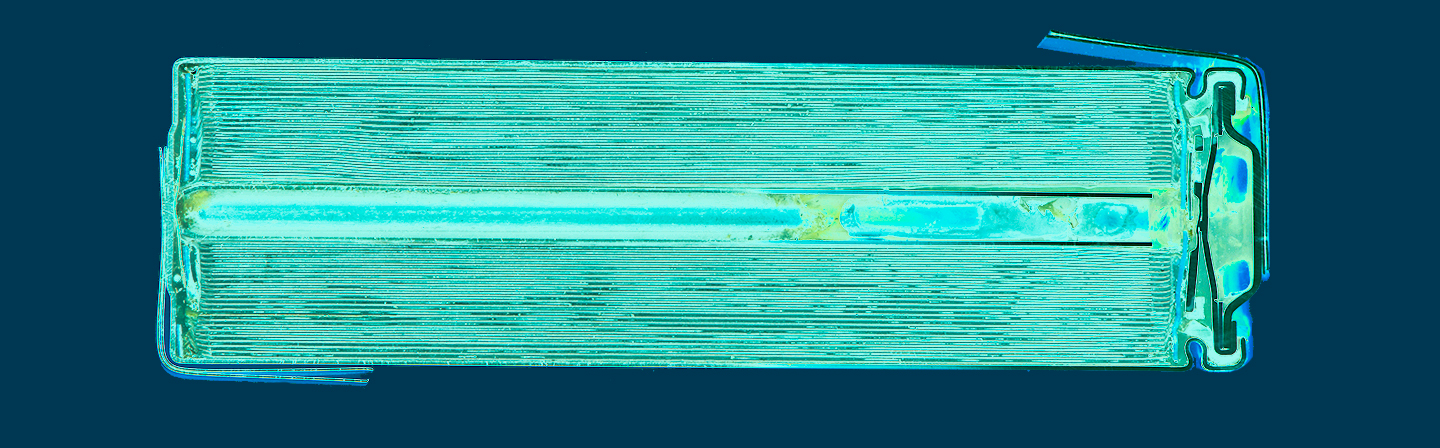

The Fraunhofer R&D Center for Electromobility Bavaria at the Fraunhofer ISC Würzburg offers materials and component development for current and future battery and storage systems. The particular focus is on lithium-ion batteries, solid-state batteries and lead-acid batteries.

High-performance lithium-ion batteries are increasingly used in everything from computers, cell phones, multimedia devices, small electrical appliances, small tools, bicycles and electric vehicles to battery storage power plants. With our know-how and our material and process development we support, e.g. automotive suppliers, battery or cell manufacturers and material developers.